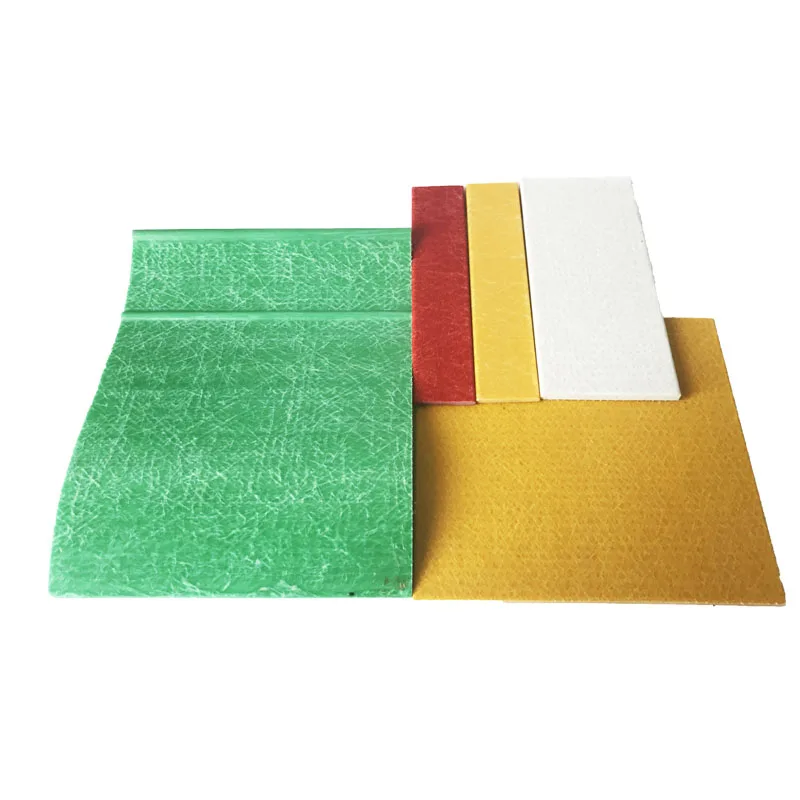

Fiberglass Outdoor Cable Tray With Cover | Glassfiber cable wire tray

fiberglass cable tray specification list:

| item | part | dimension(mm) |

| 100mm cable tray | box | 100×65×4.6 |

| top cover | 110×30×4.6 |

| 200mm cable tray | box | 200×100×4.6 |

| top cover | 210×30×4.6 |

| 300mm cable tray | box | 300×150×5.6 |

| top cover | 312×50×5.6 |

fiberglass cable tray Features:

High strength yet light weight: | Helps save on transportation |

Corrosion resistant: | Won’t rot, rust or corrode |

Fire-retardant and nonconductive: | Helps create a safer environment |

Dimensionally stable: | Won’t shrink, swell, warp or bow |

Virtually maintenance-free: | Durable and weather-resistant for a longer life cycle |

Easy to fabricate and install: | Can be cut, drilled and assembled with standard tools |

Non-leaching: | Does not require environmentally hazardous preservatives |

Fiberglass Cable Tray Uses:

Support electrical cable in highly corrosive environments

Designed for lighter loads

Individual wiring and pneumatic tubing

Retrofitting rusting applications

Low-voltage or communications cables

Fiber-optic cables

Hydraulic or pneumatic tubing

Why do you choose the fiberglass cable tray?

Features:

Solid bottom, perforated (ventilated), or slotted construction

Corrosion resistant

High strength-to-weight ratio

High durability

Lightweight

Fire retardant

Ease of installation

Yalong Pultrusion fiberglass profile including:

fiberglass rod, round tube, channel, angle, I beam, square & rectangular tube, window frame, shutter blade, other structural profile, etc.

Above profile generally be assembled to:

Fiberglass window and shutter

Pultruded Fiberglass Grating

Fiberglass guardrail handrail fence

Fiberglass ladders and stairs

Cooling tower FRP components

filler supports, anti-freeze board, grating walkway

Fiberglass Structure and support